What should be done to avoid valve leakage?

Release time:

2024-08-14

Author:

Source:

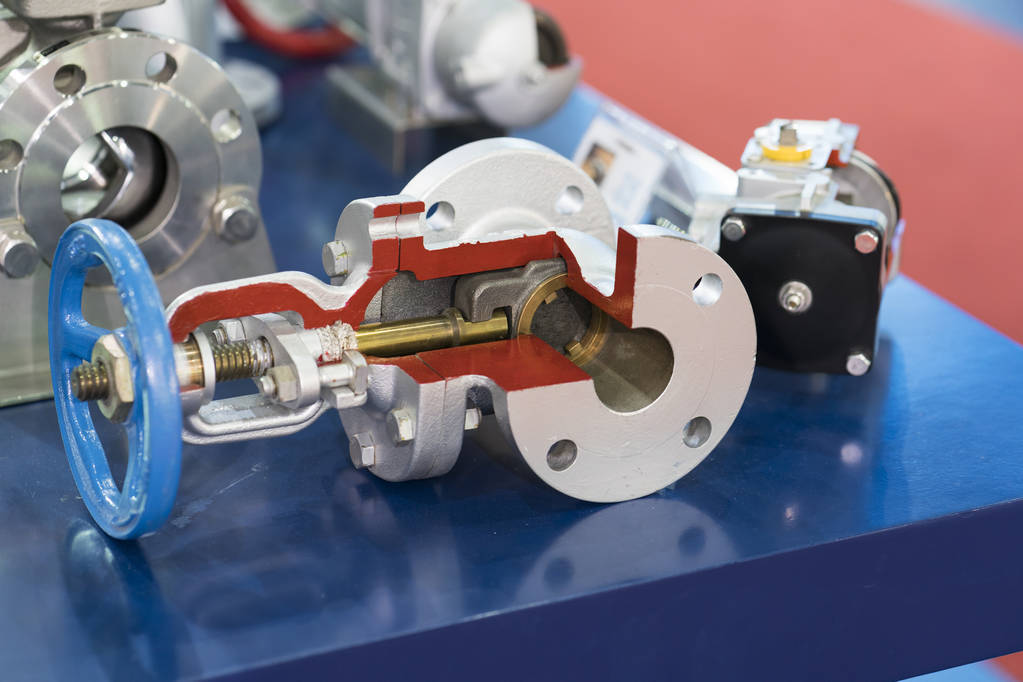

The leakage of the valve is caused by casting quality issues, but more often by the failure of the sealing pair.

The leakage of the valve is caused by casting quality issues, but more often by the failure of the sealing pair. Firstly, the internal leakage of valves is usually caused by the failure of the valve sealing pair. Secondly, aside from the factors of valve body defects, the external leakage of valves is often caused by damage to the sealing of the middle flange or valve stem packing box. In practical work, to avoid valve leakage, the following work should be done as much as possible:

1. Standardize the design content. When designing and selecting, provide a valve specification document that includes design temperature, pressure, medium properties and status, as well as valve type, valve body and main internal material, and connection requirements. This not only strengthens the awareness of design selection, but also provides a scientific basis for valve procurement

2. Change improper operating methods. If a cut-off gate valve is used to regulate the logistics, it will inevitably accelerate the wear of the valve seat and valve plate; Worried about the valve not closing tightly, use an "F" wrench to forcefully close the valve. This not only damages the sealing surface of the valve, but also causes deformation of the valve stem.

3. Change non-standard installation methods. Improper installation methods, such as installing valves without removing welding slag or sediment from the valve body, will inevitably cause damage to the sealing surface; Electric and pneumatic valves installed horizontally do not have lifting points; Installing the handwheel downwards can cause debris to deposit at the valve cover, which can affect the sealing of the packing.

With the development of process technology and material science, and the improvement of inspection and testing methods, modern valve production can avoid valve leakage. It is crucial to design, select, install, use, and maintain well valves in a timely manner to replace any problematic ones, in order to ensure process production, control the release of hazardous materials, and reduce the frequency of leakage accidents.

Key words:

Support

HUGONG provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use HUGONG products in this process more efficient and economical!

HUGONG offer free training for customer

Find out what you need from the FAQ

To learn more about the product, please download the product brochure

Address:91, Zhongnan High-tech Yuandu Huizhi Industrial Park, Taixiang Street and Wenhua Road, Weifang Economic Development Zone, Shandong